Liebherr D98XX. Born for mining

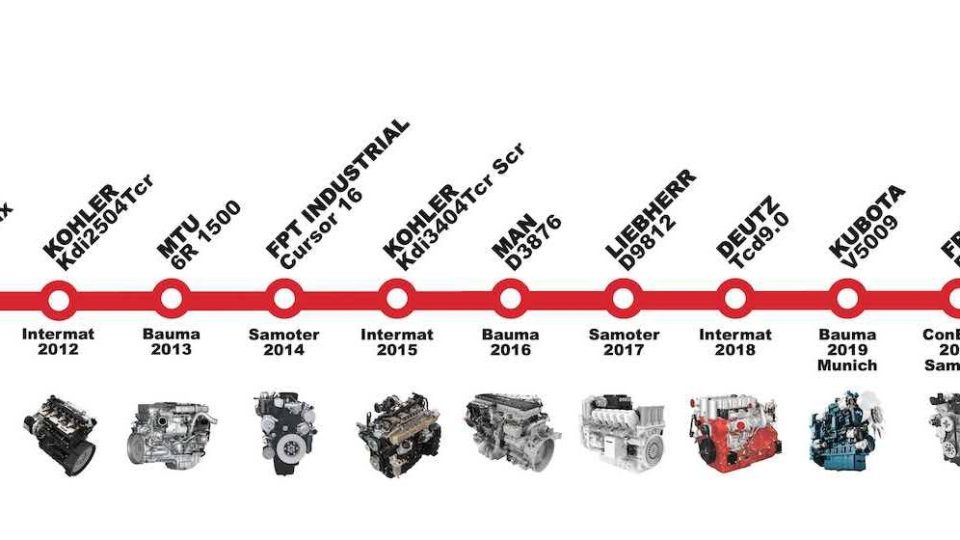

Liebherr D98XX has been designed as a mining engine. The Diesel of the year 2017 is able to operate in the most demanding environmental conditions, such as dust, humidity, in high altitude or even arctic conditions. Designed to handle low grade fuel and oil qualities, the D98 is prepared for worldwide operation, while fulfilling the […]

Liebherr D98XX has been designed as a mining engine. The Diesel of the year 2017 is able to operate in the most demanding environmental conditions, such as dust, humidity, in high altitude or even arctic conditions. Designed to handle low grade fuel and oil qualities, the D98 is prepared for worldwide operation, while fulfilling the on-site required emissions standards, be it fuel consumption optimized, Tier 2 or even the EPA Tier 4 final.

Liebherr D98XX and the harsh environments

One specific challenge for an engine working in a Mine is to deal with harsh environment. Different precaution have been taken into account when designing the D98. For example in order to keep the dirt out of the engine the D98XX series integrates a very high level of oil and air filtration measures. The quality of the sealing joints and gaskets has been chosen to withstand the harshest environments and even includes double sealing for critical components. As an ultimate redundant safety measure for dirt entering the crankcase, the use of special materials makes the engine less sensitive to oil contamination. Electrical parts, especially connectors, are designed water – and artic proof. Being a key contributor to engine reliability, engines are equipped with a robust and high quality electrical harness and a heavy duty ECU.

Liebherr D9812 up to 2.103 kW

The first cylinder variant of the series – the D9812 – which is a V12 engine, provides up to 2,125 kW (2,850 hp) in mining applications, such as dump trucks or hydraulic excavators. It also delivers outstanding low fuel consumption by matching the right engine subsystems from the highest quality of in-house developed key components, such as Liebherr engine control unit and the Liebherr common rail fuel system. The D9812 obtains fuel consumption values down to 190 g/ kWh on the test benches for certain power ratings.

This is possible due to a low mechanical friction layout and the very high peak pressure capability of the engine (up to 250 bar). Further fuel efficiency improvements result from a reduced engine rated speed (down-speeding option for excavators and trucks). The outstanding fuel consumption results in significant operating cost savings – keeping in mind that an increase of 1% efficiency can result in saving thousands of liters of fuel per year per vehicle.

Sophisticated oil and air filtration measures, heavy-duty Ecu and high quality electrical harness: these are three of the several D98XX key words to accomplish the needs of the Mine operators.