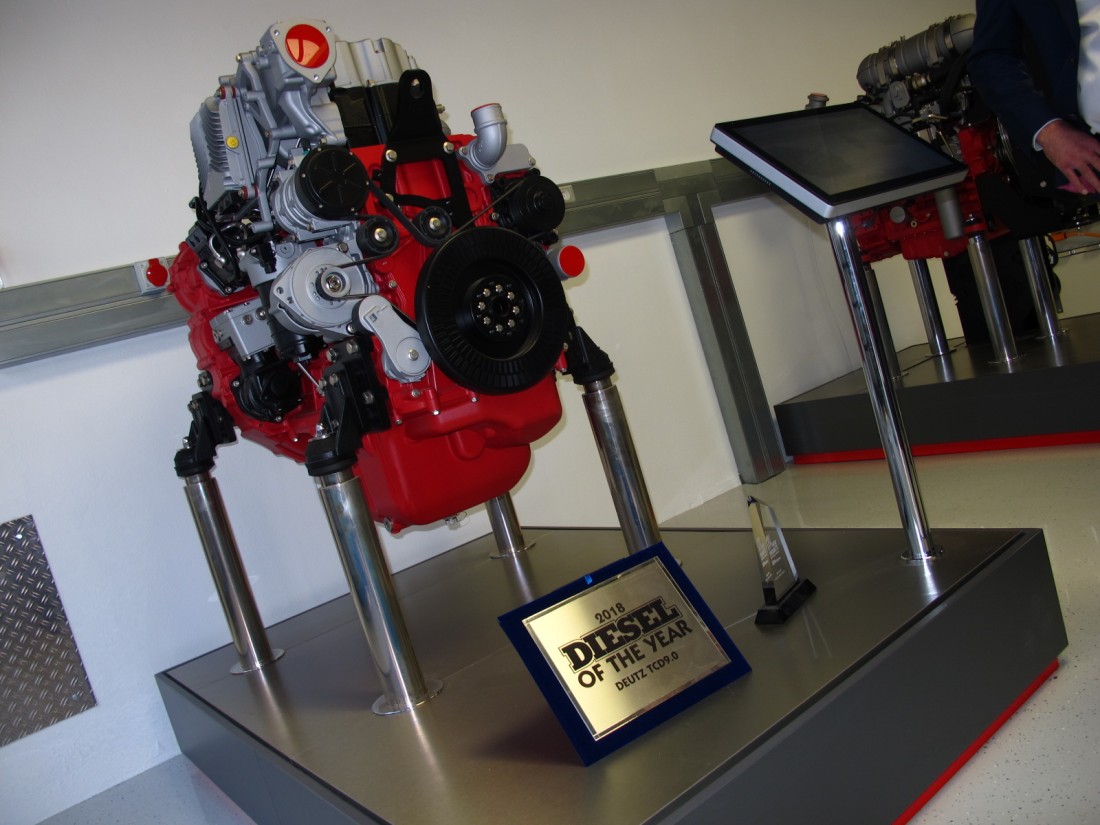

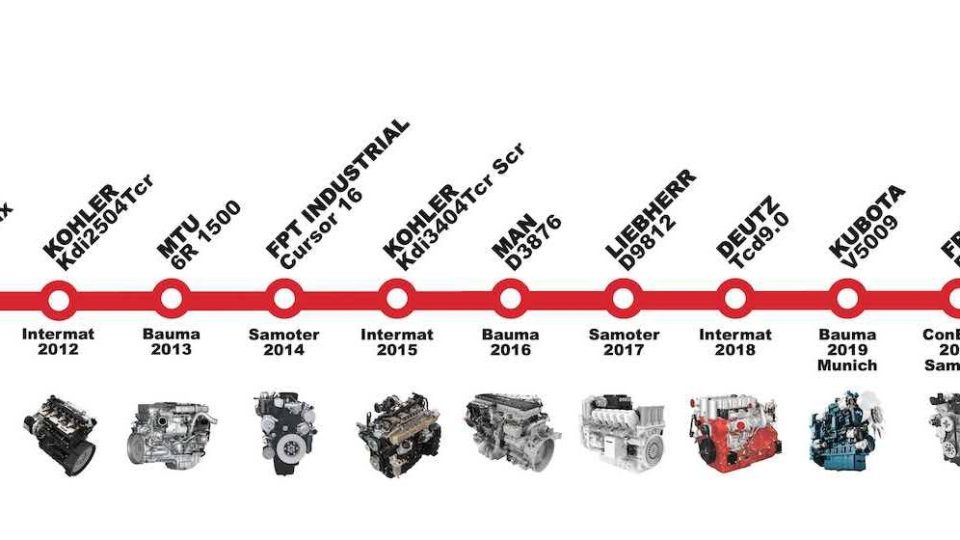

TCD9.0 Diesel of the year 2018 at Deutz Innovation Center

DEUTZ Innovation Center and ELECTRIP TCD9.0 by DEUTZ is still member of the Deutz Innovation Center. What does a boat on the Rhine, equipped with electric outboards Torqeedo and the TCD9.0 exhibited in the Deutz Innovation Center, have in common? The trait d’union is called E-Deutz and the fruits could ripen over the next few […]

DEUTZ Innovation Center and ELECTRIP

TCD9.0 by DEUTZ is still member of the Deutz Innovation Center. What does a boat on the Rhine, equipped with electric outboards Torqeedo and the TCD9.0 exhibited in the Deutz Innovation Center, have in common? The trait d’union is called E-Deutz and the fruits could ripen over the next few years. One year after the acquisition of Torqeedo, the big bang of the hybridisation and electrification project called E-Deutz, they took stock in Cologne. At the end of the event called “ELECTRIP” we witnessed the first wanderings of two demonstrators by Liebherr. These are telescopic handlers, one of the ideal applications for the electrification process.

ELECTRIP. E-DEUTZ shows itself

In the case of DEUTZ the first steps start from the TCD2.2 and the TCD2.9. The 2.2 litre diesel-engine, the odd one that comes from the modular version of the 2.9 litre, without a cylinder, at 56 kilowatts rating, is matched with a 48 Volt electric motor capable of 20 kilowatts. The transmission with integrated decoupler ensures the mechanical connection between the combustion engine and the electrical one, allowing the disconnection of the diesel from the electrical system and powers the machine in ‘zero emission’ mode. The ICE power, converted to the generator mode, is stored in a battery pack with a capacity of 10 kilowatts. The telescopic handler equipped with this system could achieve a fuel saving of up to 15 percent. This use could be extended to other small and medium-sized equipment such as mini-excavators and backhoe loaders, skid-loaders and, perhaps, to specialized tractors for vineyards and orchards.

Michael Wellenzohn, member of the Board of Management of DEUTZ AG for Sales, Service & Marketing, explains:

«We foresee particularly strong potential for installing hybrid and full-electric drives in small and medium-sized equipment. From illustrative Total Cost of Ownership (TCO) calculations, it is possible to see the period over which a hybrid drive, for example, in a particular application will cover its investment cost. Depending on the customer application, this can be after as little as one year of use. In 2022/2023, DEUTZ plans to achieve between 5 and 10 per cent of its overall sales revenue from electrified drives».

TCD 9.0 and E-DEUTZ?

The TCD9.0 will therefore have to wait. Yet this hybrid architecture could be suitable for maxi-excavators that can combine the 300 kilowatts of the 9 liters with some dozen kilowatts to satisfy the need for a 13 liters, with a strongly downward curve of diesel consumption.